Asbestos-free, rolled material, flexible, metal-free.

Base materials: Synthetic resin / caoutchouc, reinforced with synthetic fibres, fillers.

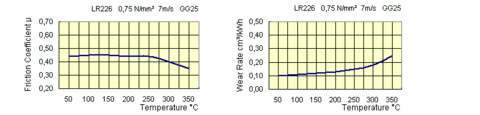

High level of friction coefficient, medium temperature range, high repetitive accuracy.

Low noise level, punchable, gentle to the counter-material.

Band- and drum brakes, light vehicle construction etc.

Very good bonding behaviour. Under oily conditions (not yet tested) bear in mind the reduced

friction factor.

Rolls, Standard roll 3,75 m and 5 m lenght, thickness 3-8 mm, max. Width 100 mm.

Thickness (mm) 3 - 4 - 5 - 6 - 8

Rolls, finished parts according to customer drawing, band- and drum brakes.

With brake disc riveted or bonded friction linings as finished machine parts.

| Tensile Strength | 14 N/mm2 | Debsity | 1,90 g/cm3 |

| Compressive Strength | 58 N/mm2 | Rivit Holding Capacity | 74 N/mm2 |

| Shear Strength | 9 N/mm2 | Hardness Shore (D) | 67 |

| Friction Coefficientdyn | 0,43 | Max. Continuous Temp. | 250 °C |

| Surface Pressure | 1,5 N/mm² | Max. Intermittent Temp. | 350 °C |

| Rubbing Speed | 20 m/s | Wear Rate | 0,13 cm3/kWh |

Recommended mating surface: Perlitic cast iron or steel hardness HB30 => 180

* The data are for your guidance only and do not render the application-specific testing unnecessary.

Accordingly, we cannot guarantee their accuracy as there are lots of possible applications.

The operating values are maximum values which must not occur simultaneously. Observe safety values!

The temporarily permissible temperature - measured on the pulley - may occur for only a few seconds.

For special applications we recommend you to consult our application engineers.