Asbestos-free, woven material rolls, flexible, metal-free, hygroscopic, colour medium to dark brown.

Extremely robust cotton fabric (fibre), impregnated with special resins.

Very high level of friction coefficient, low temperature range, great strength, gentle on the mating surface.

Permanent deformation after heating (pre-bent parts, cone rings etc.).

Used for general brake manufacture, hoisting gears, textile machines, conical brakes, separators etc.

Very good riveting behaviour. Not suitable under oily conditions.

Rolls, Standard roll 10 m length.

Thickness (mm) 5 - 6 - 8 - 10 - 12 - 16 - > upon request

Width mm: 30 - 300.

Rolls, lenghts of tape cut to size lengths of tape, plates, cone rings, ring segments, drum linings,

band brakes, holding brakes, thermoformed or prebent finished parts, friction pads riveted with

brake disks as ready-to-install machine parts.

| Tensile Strength | 28 N/mm2 | Density | 1,10 g/cm3 |

| Compressive Strength | 42 N/mm2 | Rivet Holding Capacity | 74 N/mm2 |

| Shear Strength | 13 N/mm2 |

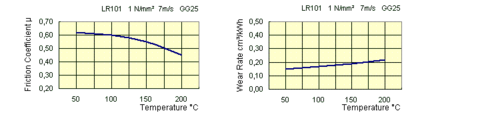

| Friction Coefficientdyn | 0,55 | Max. Continuous Temp. | 100 °C |

| Surface Pressure | 15 N/mm² | Max. Intermittent Temp. | 150 °C |

| Rubbing Speed | 20 m/s | Wear Rate | 0,20 cm3/kWh |

Recommended mating surface: GG25 or HB30 steel => 140 or higher quality.

* The data is provided for your guidance only and cannot be a substitute for application-specific testing.

Accordingly and in view of the many potential applications, we cannot guarantee its accuracy.

The operating values are maximum values which must not occur simultaneously. Safety values must be observed!

The temporarily permissible temperature - measured on the drum - must occur for only a few seconds.

For special applications we recommend that you consult our application engineers.